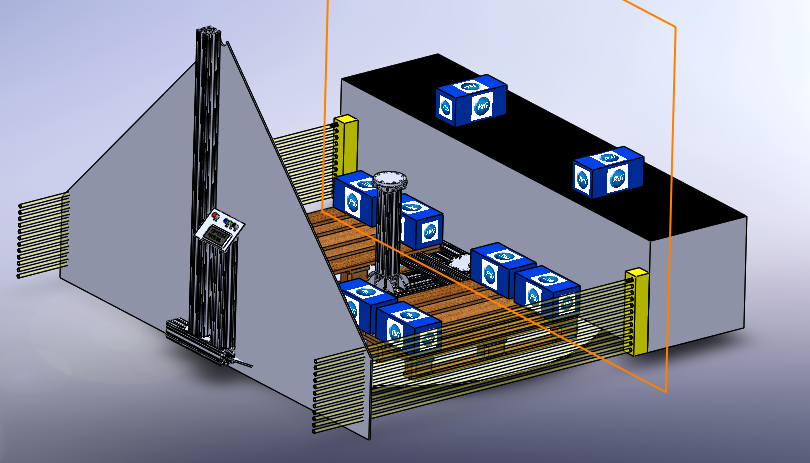

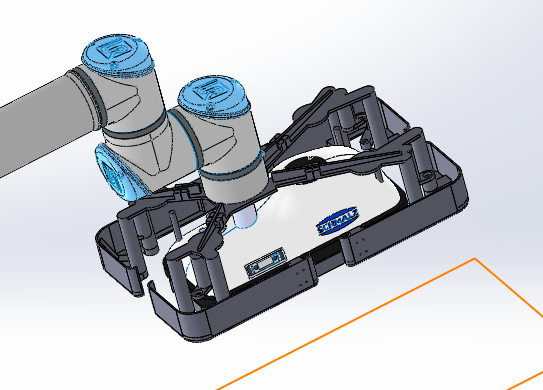

Abstract: It is a project that involves palletizing the boxes coming from the Orkid production line with an industrial robot arm with high sensitivity to safety. The system is designed to be portable. It can be easily moved from one end of a line to another. In addition, special studies have been carried out on safety. In the project, which was created using products with a high level of security, an extra special safety system was also designed for the gripper environment. During palletizing, the robot arm carries itself to the pallet height with the SKF LiftKit and performs the stacking operations on the top rows. Since pallets can be placed on both sides, pallet picking and feeding can be done without stopping the robot.

Task in the Project: Project Manager; performing engineering studies on mechanical, electrical-electronic and software, undertaking the management of the project

Equipment Used in the Project

Universal Robot UR5e

SKF LiftKit

Schmalz FXBC Gripper

Pilz Area Scanner

Pilz Light Curtain

3D Printer

Programs and Software Used in the Project

RoboDK

SolidWorks

URCap

Comments